Chinese scientists propose a one-step battery recycling process

In recent years, in response to the global environmental crisis and to reduce carbon emissions, countries have been actively promoting new energy vehicles. According to statistics, since new energy vehicles entered the passenger car market in 2014, the production and sales of new energy vehicles have continued to increase.

By 2024, the production and sales of new energy vehicles in China will be close to 10 million, and the share of new energy vehicles in the Chinese automobile market will exceed 30%. It is worth noting that according to the average service life of power batteries of 5-8 years, the power batteries of new energy vehicles promoted in China in the early stage have gradually entered the "retirement" period.

If waste batteries are not properly handled, the heavy metals and harmful chemicals they contain will cause serious pollution to soil and water resources, threatening the balance and stability of the entire ecosystem.

It is estimated that by 2030, the waste power batteries generated by new energy vehicles will exceed 3 million tons, but the standardized recycling rate of power batteries for new energy vehicles in China is less than 30%. Therefore, the recycling and treatment of waste power batteries has become the focus of attention in the industry.

On May 14, 2024, Chinese scientists published an article on the sustainable recycling of retired power batteries in the journal Nature Sustainability, which is expected to accelerate the promotion and application of advanced power battery recycling technologies and promote the rapid commercial development of the battery recycling industry.

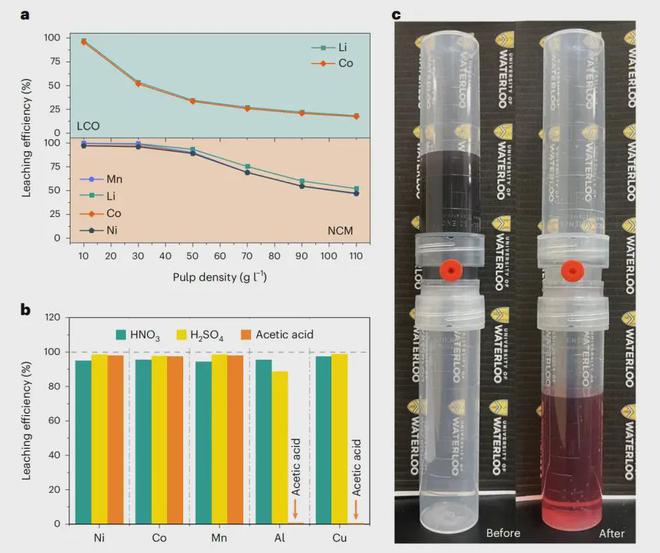

In this study, the authors used two reactions, leaching and coprecipitation, to achieve the extraction of high-value metal elements in lithium battery positive electrode materials and the regeneration of electrodes. During the leaching process, the authors used the different dissolution efficiencies of different metal elements in acetic acid to selectively dissolve high-value metal elements in lithium battery positive electrode materials, including lithium, cobalt, nickel and manganese, and then filtered to obtain clear and transparent leachate.

In order to maximize the retention of the high added value of lithium battery positive electrode elements, the authors used a mixed solution of ammonia and sodium hydroxide to coprecipitate the leachate to prepare spherical precursors in a continuous stirred tank reactor.

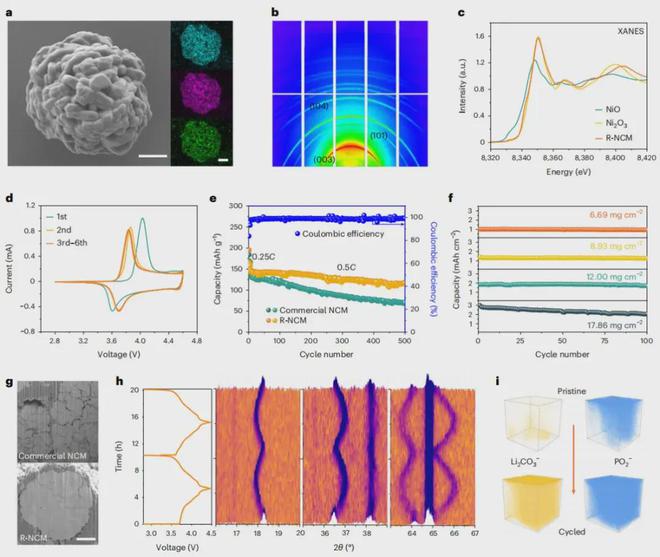

Among them, ammonia as a chelating agent can form metal-ammine complexes with transition metals in the leachate to prevent phase separation precipitation during coprecipitation. During the coprecipitation process, in addition to lithium ions, more than 99.8% of high-value metals were recovered through spherical precursors with designed proportions of nickel, cobalt and manganese. Finally, after a high-temperature lithiation reaction, the regenerated R-NCM cathode material was obtained.

Extraction of high-value elements (a. Relationship between metal dissolution efficiency and slurry concentration; b. Comparison of the dissolution efficiency of metals in lithium batteries by different types of acid solutions; c. Vacuum-assisted filtration.)

The experimental results show that the R-NCM regenerated cathode material exhibits high reversible capacity and high coulombic efficiency (>99.7%). In terms of stability, the capacity retention rate of the cathode material after 500 charge and discharge cycles is 81.2%, which is better than that of the commercial NCM cathode material (capacity retention rate is 50.1%), and the regenerated cathode material retains the spherical structure of the precursor, with extremely small microcracks during the cycle and strong phase stability.

Compared with commercial NCM cathode materials, the production and use of R-NCM renewable cathode materials can effectively reduce the potential for global warming and the scarcity of fossil resources. In terms of battery cost, the use of R-NCM renewable positive electrode materials can reduce the manufacturing cost of lithium-ion battery packs and sodium-ion battery packs by $21.65 per kWh and $41.67 per kWh, respectively.

Lithium-ion battery recycled positive electrode materials (a. SEM image and element distribution map of spherical R-NCM powder, nickel (blue), cobalt (pink) and manganese (green), scale is 1μm; b. Two-dimensional GIXRD image; c. K-edge XANES spectrum of nickel; d, e, f. Electrochemical performance characterization results; g. Cross-sectional FIB electron microscope images of commercial NCM electrodes and R-NCM electrodes after cycling, scale is 1μm; h. In-situ XRD map of R-NCM electrode and corresponding cycle curve; i. Three-dimensional reconstruction of representative materials on the electrode surface.)

What other practices are there for lithium battery recycling and reuse?

The recycling and reuse of lithium batteries refers to the dismantling of retired lithium batteries through chemical, physical, biological and other means to achieve the purpose of recovering metal elements such as nickel, cobalt, manganese, lithium and other recyclable materials. At present, the main methods for recycling and reuse of lithium batteries include wet recycling, pyrometallurgical recycling and biological recycling.

Wet recycling refers to the use of chemical reagents to selectively dissolve the metals in the electrode materials, and then separate the metal elements in the leached liquid. This technology has the advantages of high recovery rate, high product purity and low energy consumption, and is currently the most widely used recycling technology.

Pyrometallurgical recycling refers to the removal of impurities in waste batteries by high temperature means, and finally extracting fine powder materials containing metals and their compounds. This technology has a simple operation process and high efficiency, and is suitable for processing large quantities or batteries with complex structures.

Biological recycling refers to the use of metabolic processes of microorganisms to selectively leach metal elements from waste batteries to achieve the purpose of extracting high-value metal elements. This technology is environmentally friendly, but it is still in the research and development stage and the technology is not yet mature.

Environmentally friendly recycling of lithium batteries

Impact on our lives?

1. Environmental protection

Lithium battery recycling can significantly reduce the pollution of waste batteries to the environment. Through professional recycling and processing, harmful substances in waste batteries, such as heavy metals and organic solvents, can be prevented from leaking into the environment, protecting soil and water resources.

2. Resource conservation

Lithium battery recycling can achieve the reuse of high-value and rare materials. For example, recycled metal elements such as lithium, nickel, and cobalt can be used as raw materials to produce new batteries after refining and purification, reducing production costs and saving resources.

In addition, recycled battery chips and electrolytes can also be recycled or reused, further improving resource utilization efficiency.

As a new choice for environmentally friendly travel, new energy vehicles have not only brought revolutionary changes to our travel methods, but also made great contributions to environmental protection. Although the recycling technology of waste batteries can alleviate the pollution of waste batteries to the environment to a certain extent, it is still recommended that we develop good car-using habits in daily life, extend the service life of batteries, reduce the generation of waste batteries, and contribute a green force to the earth's environment.

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish